COSMYX X ORANGE: 3D PRINTING ACCELERATED BY 5G

- elsapettirossi

- Jul 16, 2024

- 3 min read

Discover in video our partnership with Orange and its subsidiary Viaccess-Orca around an ambitious initiative aiming to achieve secure and connected 3D production via 5G for Defense purposes.

© Orange Video

A STRATEGIC ADVANTAGE FOR THE ARMED FORCES

Additive manufacturing is experiencing rapid growth due to its ability to create custom objects on demand and near end-users. For the armed forces, the capability to quickly repair equipment in the field is essential. It is in this context that our collaboration with Orange and Viaccess-Orca has been implemented to securely produce spare parts near military operational zones. This initiative, undertaken in partnership with KNDS France (formerly Nexter), the French branch of the Franco-German defense group KNDS, aims to design spare parts for the NERVA ground robot, a KNDS France equipment used notably by the French armed forces.

"For ground forces, occupying territory prevents enemy advancement while preparing for their own progress", says Sylvain Kahoun. "The corollary is the need to maintain and repair equipment promptly on the battlefield, even proposing an emergency definition with associated employment limits in operational urgency where the need for regeneration of potential can make a difference."

As the project lead for additive manufacturing at KNDS France, Sylvain Kahoun underscores the importance of maintaining and repairing equipment in the field, a critical aspect of "maintenance in operational conditions" (MCO). Through 3D printing, armed forces can urgently produce spare parts, bypassing logistical challenges of delivery in difficult or hazardous zones.

A SECURE MANUFACTURING AND DEFINITION

While decentralized 3D printing offers numerous advantages, it also presents a significant challenge: secure connectivity. In the context of a military-industrial project, the integrity and sovereignty of manufacturing data are crucial, and any leakage of confidential information poses an unacceptable risk.

"With digitalization comes cyber threats", explains Perez Pelage, Head of Emerging Business overseeing the industrial sector at Viaccess-Orca. "Our security solution ensures that high-value content and intellectual property are protected with confidentiality and integrity across the entire production chain, from design offices to production centers, through the platform storing digital models."

The content created by KNDS France is encrypted and signed by Viaccess-Orca's security solution, then decrypted at our Cosmyx 3D printers. Viaccess-Orca's security solution also empowers data owners to regulate file usage by specifying permissions for users, types of printers, periods of use, and materials employed.

AN OPTIMIZED 3D MICRO-FACTORY POWERED BY 5G NETWORK

Having defined their specifications to meet the French Army's additive manufacturing needs, KNDS France and Viaccess-Orca needed to identify a 3D printer suitable for the demands and constraints of this exacting sector. With experience collaborating with international industries and armed forces, we were already well-versed in the connectivity and security requirements for such requests.

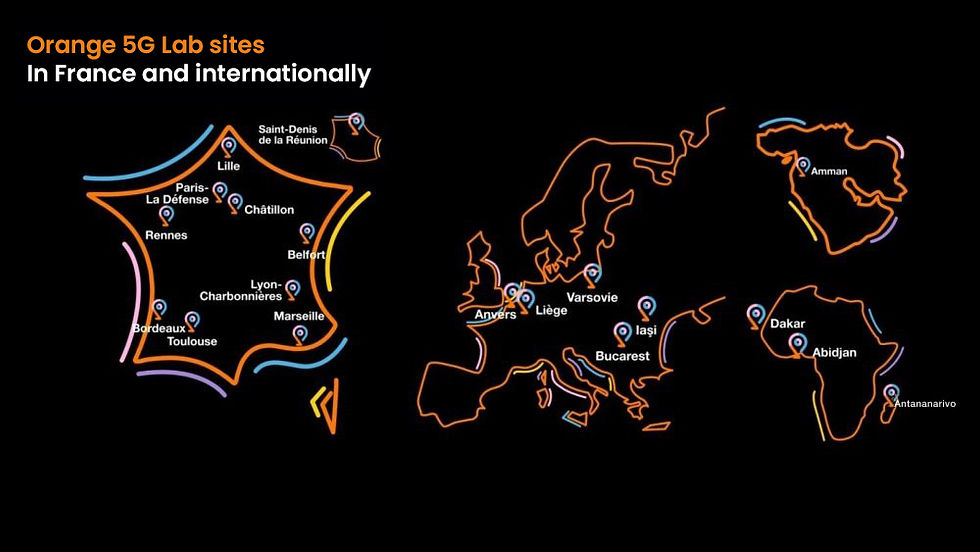

Our partnership was solidified through the Orange 5G Lab program.

"It was during a visit to the Orange 5G Lab showroom in Châtillon that I met the Cosmyx team", recalls Frédéric Havard, Director of Innovative Projects for the Île-de-France region at Orange France. "Strong connections quickly formed because Cosmyx sensed that 5G would open doors to multi-stream control."

3D printing is an excellent use case to showcase the key qualities of 5G, especially security, throughput, and latency. An Orange 5G starter kit was promptly provided to integrate into our 3D solutions.

"The advantage of our proposition is that technical knowledge remains within the design office", emphasizes Anthony Seddiki, founder of Cosmyx. "We provide guarantees in production integrity and repeatability, while leveraging the agility of 5G."

The performance and operational maturity of our Cosmyx 3D printers, coupled with Viaccess-Orca's advanced encryption solution, convinced KNDS France of the relevance of this combination to effectively meet urgent technological needs.

A SUCCESSFUL CASE STUDY AND A RELEVANT CHALLENGE MET

After an evaluation phase, a demonstration under real conditions was conducted in June 2023 with KNDS France and Viaccess-Orca using the NERVA robots, remotely operated ground drones used by the French armed forces.

Two use cases were presented during the first edition of the Additive Manufacturing Village, organized by the European Defense Agency. Firstly, the implementation of an encryption solution to prevent unauthorized reproduction and dissemination of the design of a temporary part, tailored to the specific needs of an operational context. Secondly, the design of a replacement part for an urgently needed defective track drive wheel, with characteristics as close as possible to the original component, and capable of being printed using resources and materials available in the field.

"This demonstration proved highly convincing, as military personnel from other nations could see firsthand that 3D printing has the capability to produce a replacement part in just a few hours, enabling the repair of the robot and ultimately fulfilling the mission," asserts Anthony Seddiki.

This presentation reaffirms the strategic importance of secure 3D printing, particularly during times of escalating geopolitical tensions.

With our 3D printers located within two Orange 5G Labs, we are now the sole providers offering integrated production chain security solutions compatible with the 5G network!